We hear some say that life used to be simpler in the old days. While this sentiment is mostly connected with the way human brain suppresses negative memories and we thus tend to remember our past in rosy colors, at a first glance the same could be said about the applicability of the DO-254 standard in the Airborne Electronic Hardware development.

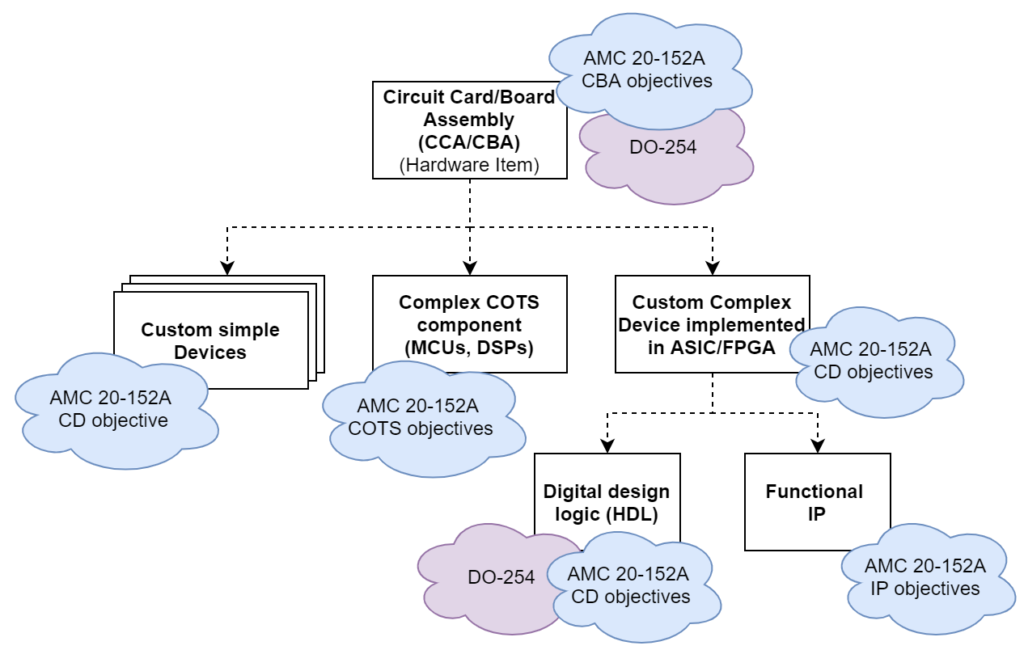

When you ask about this someone who has designed the electronic hardware in Aerospace in the past the answer they will give you will be that DO-254 was used only for the design of complex custom devices – that is the Programmable Gate Arrays (be it in a form of PDL, CPLD or FPGA) or Application Specific Integrated Circuits (ASIC). The rest of the development that included Circuit Control Board and mechanical aspects were only developed – somehow – so that they passed the functional tests and the Environmental Qualification tests as prescribed by DO-160() standard. Or were they?

The first thing that most folks tend to forget is that as Aerospace suppliers their company had to meet the AS9100 standard. As such there are many objectives related to the rigor, planning and control of the development effort that had to be met and had to be somehow incorporated into company’s plans, procedures, processes and standards. These were then followed when the Airborne Electronics Hardware was developed.

The second thing that is taken for granted is that any organization has it’s lessons learned and best practices – either it was collected at a formal level and deployed in a form of formal standards or other documents, or there were senior developers who followed whatever best practices they have learned based on their experience and most likely advised and informally checked their colleagues’ work as well.

As such one could say that there were in fact some best practices and more or less formalized plans, procedures, processes and standards in place even in the old days… So how much different was it from what the DO-254 requires? Not much as DO-254 is in fact a collection of best practices collected by the Aerospace companies and their Electronics Development teams and put into writing by their most senior experts – those are the same people with the same knowledge and experience who developed the Airborne hardware and advised their colleagues to follow these best practices!

So what is the situation now with the updated AMC 20-152A/AC 20-152A + AC 00-72? Not really radically different one might say.

The first thing that we notice is the objective CBA-1 that says that if there is no Complex hardware used the development of the Circuit Board Assemblies does not need to follow DO-254 and you could design your electronics hardware product only based the allocated System requirements without a formal process in place. You still need to create a PHAC where you would justify that no complex component is used/designed, Hardware Verification Plan as a standalone document or as a part of the PHAC to show how do you plan to do the comprehensive combination of deterministic testing and analysis required for the simple hardware, Hardware Accomplishment Summary to show compliance and Top-level drawing and/or the Hardware Configuration Index to identify your product and its production baseline AND it all needs to be archived and controlled via some Configuration Management process.

The next level is when your design does contain a Simple Custom Device implemented in a programmable gate array (multiplexer, shift registers, etc.) – then you are required to have a simplified Development Assurance process in place for its development. Such simplified process is most likely already in place – as we have discussed before – and not much additional work will be needed here. It just needs to cover the definition of: the device functions, a complete verification of the device functions through tests and analyses, Configuration management, Problem reporting and the assessment of the build conformance.

Then is the already familiar full DO-254 suite for the Complex Custom Devices that we already know and love 🙂

Last but not least the new objectives from AMC/AC 20-152A do aim to ensure that whatever other complex components we do use in our electronics (ranging from COTS devices like CPUs/DSPs/etc. to ready to use design blocks/netlists for our Custom devices) do meet roughly the same objectives and standards as our internally developed ones.

So here we are – a lot of the activities that the updated AMC/AC 20-152A formalized in the form of new objectives were most likely already somehow in place or taken into consideration and there is not really that much additional work for us to do. We just might need to formalize some of our thought processes and best practices and document results of the analysis and thinking we do when we do design our electronics and select and use our components to convince the regulators that we – as experienced designers – have learned our stuff and are able to take all the various aspects of developing Airborne Electronics Hardware into consideration so that the final product meets all the safety, quality/functionality, integrity/reliability and maintainability requirements this domain needs.

If you want to know more about these objectives there is Introduction to DO-254 and AMC 20-152A webinar I have prepared for PTC that discusses these in more details.

by M. Tomsu